Client-Owned Design: A Non-Disclosure Agreement (NDA) will be signed to strictly protect the client’s intellectual property.

Selection from Our Designs: We will provide our existing styles based on the client’s preferences for selection.

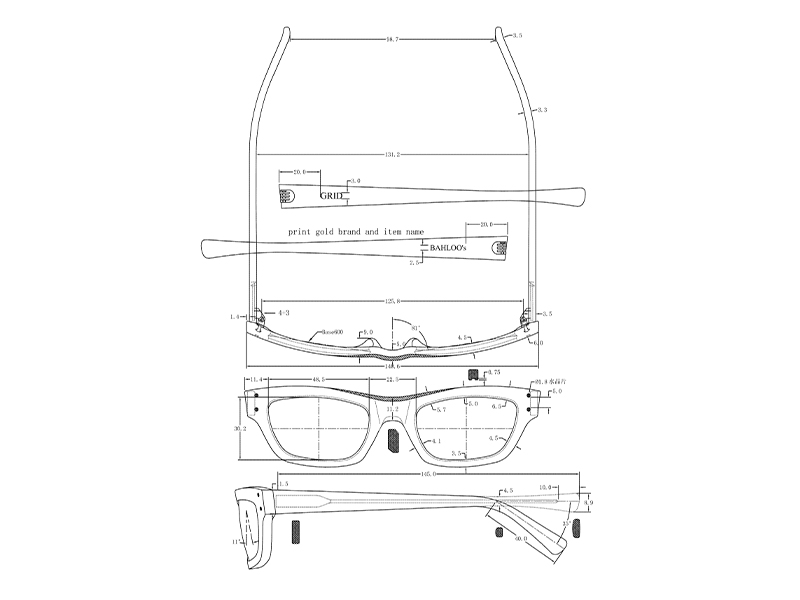

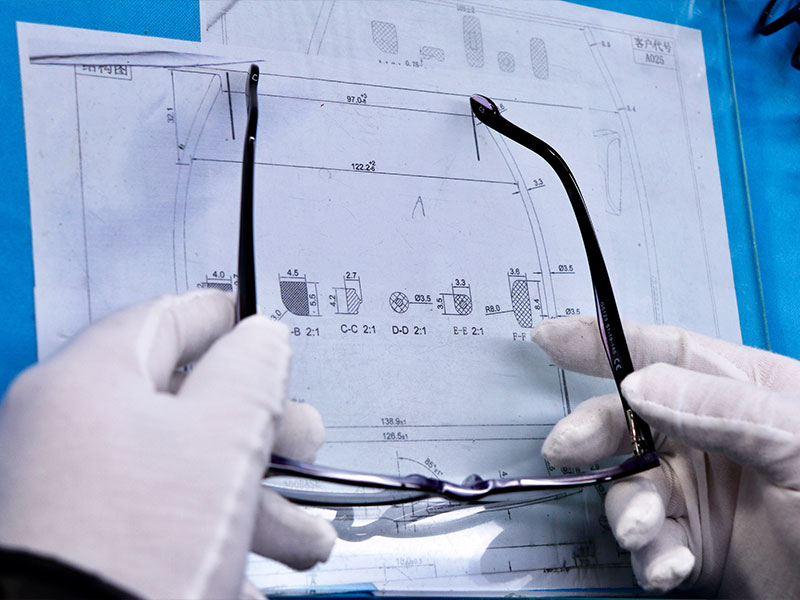

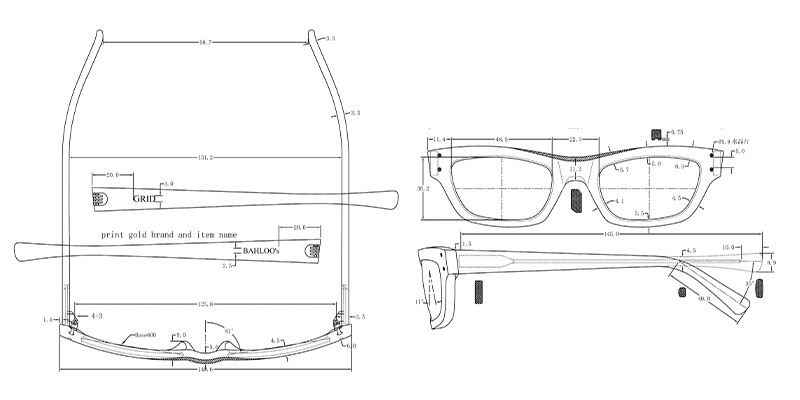

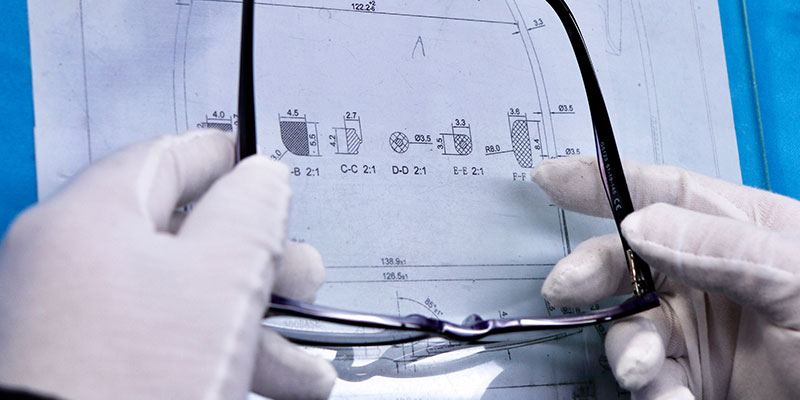

Custom Design: Our designers will create unique, original designs according to the client’s specific requirements.

Proceed to the next step upon design confirmation.

Detailed communication to clarify all product specifications (e.g., materials, dimensions, colors, functions,logo solution…).

Joint discussion to determine feasible production solutions.

Provide a detailed quotation for client review based on the confirmed solution.

Proceed to the next step upon client approval of the quotation.

Standard Process (Sufficient Time):

Confirm all details and sign a sampling order with the client.

Complete sample production and ship to the client for testing and evaluation.

Client confirms bulk order quantity and any necessary modifications based on sample evaluation.

Expedited Process (Tight Deadline with Defined Sales Date):

Skip formal sampling; produce a Pre-production Sample (PP Sample) for rapid client confirmation of key elements.

Proceed directly to bulk production upon PP Sample approval.

Proceed to the next step upon sample/PP Sample confirmation.

Commence bulk production.

Rigorous Quality Management: Dedicated Quality Control (QC) inspectors are stationed in each production workshop for real-time monitoring and inspection throughout the entire process.

Final Inspection: A comprehensive final quality inspection is performed before packaging.

Quality Assurance: Non-conforming products identified during inspection are immediately reworked to ensure all final deliverables meet quality standards.

Standard Packaging:

Per Pair: Protective plastic bag (transparent OPP) + inner soft pouch.

Inner Carton: 10, 12, or 16 pairs packed in one white carton.

Master Carton: White cartons packed into the shipping carton.

Custom Packaging:

Provide tailored solutions based on specific client requirements (e.g., microfiber cloths, hard/soft cases, chains, barcodes, hangtags, gift boxes).

Source necessary accessories as required.

Complete packaging strictly according to client specifications.

Shipping Preparation:

Prepare and send the Packing List to the client for confirmation as requested.

Logistics Arrangement:

Client-Designated Freight Forwarder: Ship goods to the specified forwarder’s warehouse per requirements.

Our Logistics Arrangement: Provide 2-3 shipping methods with varying pricing and transit times for client selection.

End-to-End Tracking: The assigned sales representative will track shipment status continuously until client receipt.

Clients can contact us anytime for prompt resolution of any post-delivery issues.

We proactively maintain communication to support future new product development.

Client-Owned Design: A Non-Disclosure Agreement (NDA) will be signed to strictly protect the client’s intellectual property.

Selection from Our Designs: We will provide our existing styles based on the client’s preferences for selection.

Custom Design: Our designers will create unique, original designs according to the client’s specific requirements.

Proceed to the next step upon design confirmation.

Detailed communication to clarify all product specifications (e.g., materials, dimensions, colors, functions,logo solution…).

Joint discussion to determine feasible production solutions.

Provide a detailed quotation for client review based on the confirmed solution.

Proceed to the next step upon client approval of the quotation.

Standard Process (Sufficient Time):

Confirm all details and sign a sampling order with the client.

Complete sample production and ship to the client for testing and evaluation.

Client confirms bulk order quantity and any necessary modifications based on sample evaluation.

Expedited Process (Tight Deadline with Defined Sales Date):

Skip formal sampling; produce a Pre-production Sample (PP Sample) for rapid client confirmation of key elements.

Proceed directly to bulk production upon PP Sample approval.

Proceed to the next step upon sample/PP Sample confirmation.

Commence bulk production.

Rigorous Quality Management: Dedicated Quality Control (QC) inspectors are stationed in each production workshop for real-time monitoring and inspection throughout the entire process.

Final Inspection: A comprehensive final quality inspection is performed before packaging.

Quality Assurance: Non-conforming products identified during inspection are immediately reworked to ensure all final deliverables meet quality standards.

Standard Packaging:

Per Pair: Protective plastic bag (transparent OPP) + inner soft pouch.

Inner Carton: 10, 12, or 16 pairs packed in one white carton.

Master Carton: White cartons packed into the shipping carton.

Custom Packaging:

Provide tailored solutions based on specific client requirements (e.g., microfiber cloths, hard/soft cases, chains, barcodes, hangtags, gift boxes).

Source necessary accessories as required.

Complete packaging strictly according to client specifications.

Shipping Preparation:

Prepare and send the Packing List to the client for confirmation as requested.

Logistics Arrangement:

Client-Designated Freight Forwarder: Ship goods to the specified forwarder’s warehouse per requirements.

Our Logistics Arrangement: Provide 2-3 shipping methods with varying pricing and transit times for client selection.

End-to-End Tracking: The assigned sales representative will track shipment status continuously until client receipt.

Clients can contact us anytime for prompt resolution of any post-delivery issues.

We proactively maintain communication to support future new product development.

Customized

service content

Our in-house R&D team delivers custom development solutions tailored to your needs !

Customized

service content

Our in-house R&D team delivers custom development solutions tailored to your needs !

Our in-house R&D team delivers custom development solutions tailored to your needs !